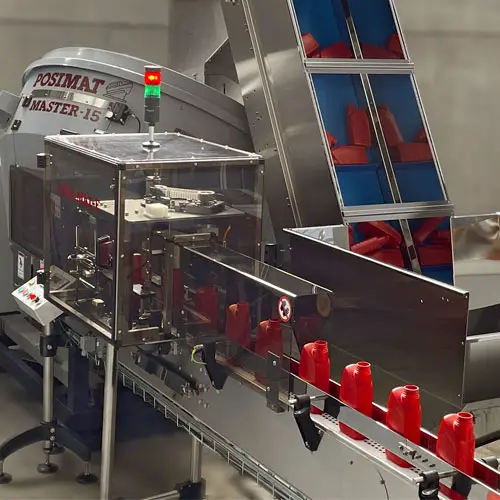

A rotary bottle unscrambler for a filling line is a mechanical device that automatically organizes and orients bottles entering in a disordered manner, aligning them in the correct direction (neck up) to be filled. It uses a rotating system based on gravity and air to ensure efficient and uniform feeding of containers to the production line.

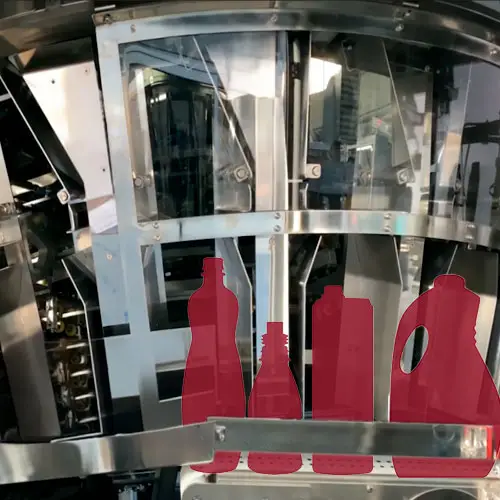

Suitable for any type of plastic container, with no restrictions on size, material, or shape.

POSIMAT offers a solution tailored to each particular industrial sector.

Unique Advantages of Posimat Plastic Bottle Unscramblers:

Plastic bottle unscramblers, characterized by their simplicity of operation, efficiency, and virtually zero maintenance. Suitable for a wide variety of bottle shapes and sizes.

Format change simply by plugging and unplugging the new format selectors/funnels, without the need for tools or adjustments. These format changes can be easily performed by a line operator in a short amount of time.

The N series Access bottle unscramblers for plastic bottles are known for their simplicity of operation, efficiency, and virtually maintenance-free design. Suitable for a wide variety of bottle shapes and sizes. Format change is simply done by plugging and unplugging selectors/funnels for the desired format, without the need for tools or adjustments. These format changes can be easily performed by a line operator in a short period of time.

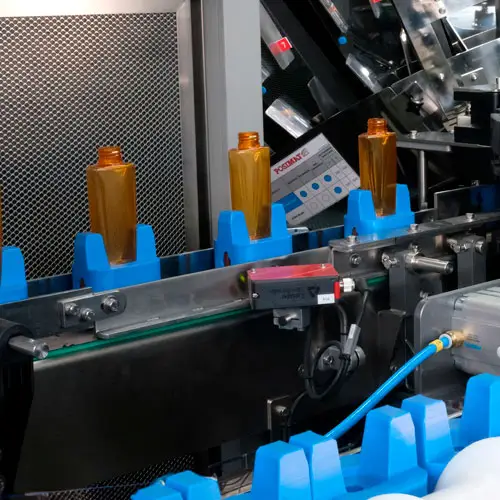

Optionally, bottles can be transported by pucks.

It is the only fully adjustable automatic format change system on the market, activated by simply pressing a button. This system is available in the Access, Monochute, and Multichute series of unscramblers.

The advantages provided by the POSIFLEX system include quick format changes (instantaneous, in less than 1 minute) and the flexibility to add future formats by entering the parameters of the new bottle through the HMI.

Especially suitable for industries dealing with many formats, as it saves changeover time storage room for the change parts.

Whether it's because bottles are unstable or in other to optimize flexibility and speed in line format changes, some lines transport bottles inside pucks (also called godets).

The POSIPUCKS unscrabler perfectly inserts bottles into pucks and can also utilize any of POSIMAT's format change systems: manual or automatic.

The pucks enter empty from the end of the line and all of them exit the unscrambler with a bottle inside. No puck is sent to the filling line without a bottle.

The combination of a bottle unscrambler with a Bottle Transfer Unit (BTU) allows for the safe transfer of unstable bottles to the filler. The BTU transfers the bottles into pucks (also known as godets).

Bottles can be transferred with or without prior orientation (depending on whether the bottle or puck is asymmetrical) to be inserted into the line's pucks.

The system is compatible with various types of pucks, including free-fall pucks, pucks with sides for labeling, asymmetrical pucks, etc.

Designed for unscrambling plastic tubes for any industry: cosmetics (mascara, dental hygiene, etc.), construction/DIY (silicone tubes), plastic cartridges of any type, etc.

POSIMAT tube unscramblers can deliver containers horizontally, side by side, presenting them transversely to the next machine: screen printing equipment, filler, etc.

Tube unscramblers can be manufactured in MASTER or ACCESS execution.

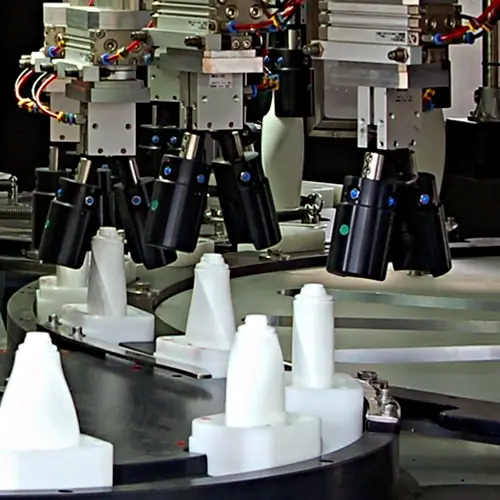

The POSIBOT is designed to work with all types of containers and other objects of different geometric shapes, especially those with very similar base and height size.

It features a system with suction cups that rotates the containers or objects to be unscrambled between 0º and 360º and gently places them on the output conveyor automatically, without pressure.

Format change is done by manually replacing the format parts without the need for adjustments or tools, in less than 5 minutes and without the involvement of qualified personnel.

This model is specially designed to operate fully automatically, without a dedicated operator.

The MONOCHUTE and MULTICHUTE series are high-production models of bottle unscramblers suitable for all types of bottles and shapes, including bottles with flat or petaloid bases. They are the perfect ally to ensure high Overall Equipment Effectiveness (OEE) in any industry (soft drinks, water, dairy beverages, cosmetics, detergents, lubricants, etc.). Suitable for lines with or without pucks (also known as carriers).

The operating system is standard for all POSIMAT equipment, utilizing only gravity and air: no ramps, hooks, pulleys, or springs that may become misaligned.

Its ACCESS-type cabin allows for total control from the outside as well as access for inspection, cleaning, and lubrication (CIL).

The POSIPHARMA bottle unscrambler is designed to unscramble wide-mouth bottles and large-diameter caps at productions of up to 300 bpm.

Its format change is done by manually changing format parts without the need for adjustments or tools, in less than 5 minutes and without the need for qualified personnel.

Specially designed model to operate fully automatically, without the need for dedicated operator supervision.

A small bottle unscrambler, typically for ophthalmic drops of 5ml and 10ml. Compact design capable of reaching productions of up to 120 units/minute.

It does not use compressed air.

Its design adapts to the GMP requirements of each client, making it ideal for automation solutions for the pharmaceutical industry.

Centrifugal bottle sorter, specially designed for the pharmaceutical sector for small-sized containers (typically ophthalmic drops or similar of 5ml and 10ml).

The machine is designed following GMP manufacturing guidelines, applicable in the pharmaceutical and cosmetic industries.

The tools and parts in contact with the bottles are easy to remove, handle, and sterilize in autoclaves.

Does not require compressed air for operation.

The ACCESS BI-N bottle unscrambler has two bowls with a single bottle infeed and outfeed and it can reach high production speeds.

Integrating a bottle unscrambler between the blow molder and the filler provides a bottle buffer that absorbs the stops upstream and downstream of the line, increasing the total line efficiency (OEE) by more than 15%.

Posimat’s automatic bottle unscramblers are designed to maximize efficiency in production lines of any scale, from low to high production.

The Posimat unscrambler series offers three format change types: manual, semi-automatic, and fully automatic, allowing unprecedented customization and adaptability for various production environments. These format changes are quick and easy, significantly reducing downtime during production transitions and facilitating operational versatility.

Posimat’s model range includes compact systems ideal for space-limited lines and robust options for high capacity, meeting the demands of diverse industries like cosmetics and pharmaceuticals, where precision and special care in container handling is required. Additionally, for specialized lines using pucks to handle unique or delicate containers, Posimat offers specific solutions that maintain the integrity and quality of the final product. With a variety of features, Posimat’s unscramblers align with the efficiency and adaptability needed to meet current and future production challenges.

Each industry has its unique production speed requirements. At Posimat, we’ve developed empty bottle unscramblers capable of operating at different speeds, always maintaining optimal performance while using the same operating principle. Our commitment is to provide flexible solutions that adapt to both small productions and high-speed packaging lines.

We have collaborated closely with companies from multiple sectors, developing unscramblers that meet the strict standards of the pharmaceutical, food, cosmetics, and chemical industries, among others. Our equipment is designed with the specifics of each bottle type and production line in mind, always ensuring smooth and efficient integration.

Whether it’s a 5ml bottle for pharmacy or a 5L container for motor oil, POSIMAT has the unscrambler tailored to every need.

Unscrambling speeds range from 20 bpm (bottles per minute) (1200 bph) (bottles per hour) up to 1000 bpm (60000 bph).

The types of containers handled by POSIMAT include:

Quality is our priority at every stage of the manufacturing process. All our unscramblers are built using top-line components and high-quality materials, carefully selected to ensure superior performance and extended durability. From motors and sensors to control systems, we work exclusively with world-leading suppliers, ensuring each part meets the highest quality and reliability standards. Furthermore, the materials we use are designed to withstand the most demanding conditions, including high-speed industrial environments and intensive use, ensuring optimal long-term operation.

90% of our customers have more than one Posimat unscrambler in their production lines, and this is due to several key factors that set us apart in the market. The high quality of our equipment guarantees reliable and long-lasting performance, while its efficiency optimizes production processes to the maximum. Additionally, our unscramblers require virtually no maintenance, reducing downtime and operational costs. This is complemented by our world-class customer service, ensuring fast and effective support anywhere in the world. For these reasons, companies trust Posimat to continuously expand and improve their operations with additional equipment.

A bottle sorter, also known as a "bottle unscrambler," is an essential mechanical device in automated production lines. Its primary function is to automatically organize and orient bottles in the correct direction before filling. At Posimat, our rotary unscramblers use an advanced rotating system that ensures efficient and uniform container feeding, perfectly preparing them for the filling process.

The operation of a bottle unscrambler focuses on efficiency and precision. Bottles are loaded into the system, where a rotating mechanism aligns and correctly orients them using combinations of gravity and compressed air movements. This process ensures that each bottle reaches the filling line in the ideal position for error-free processing, maximizing production efficiency and minimizing downtime.

At Posimat, we are recognized leaders in the manufacturing of bottle unscrambling systems, with decades of experience and a focus on innovation and quality. Our equipment is designed to integrate seamlessly into any production line, providing reliable, high-quality solutions tailored to each client’s specific needs. To discover how our unscramblers can improve your production line, fill out the form below. Our team is ready to offer you a personalized solution that perfectly fits your business needs.