At POSIMAT, we design and manufacture custom industrial conveyors, combining technological innovation and quality to optimize your production lines. Discover our solutions for efficient and safe transportation in industries such as food, pharmaceutical, cosmetic, and more.

Whether for transporting containers in bulk (mass transport) or upright (chain conveyor, with or without vacuum, or air conveyor) POSIMAT has the engineering team to help you design the optimal solution for your line.

POSIJET, the only air conveyor with dual guidance. It efficiently handles bottles that other systems cannot transport.

A dual-guide profile encapsulates the bottle above and below the neck ring, avoiding leaving marks on the bottle neck and providing greater stability even at very high line speeds. Its unique bidirectional orifice model precisely directs the airflow around the neck ring and body of the bottle. This reduces pollution levels and jams, increases bottle speed, and keeps them upright at high speeds.

Effective with short-neck bottles. With Posijet, the airflow is precisely directed, able to concentrate on desired points of the bottle, even on short-neck bottles. Inclinations and declines of up to 90 degrees allow space savings in the production plant.

Mass conveyors have a stainless steel structure. Inside is the modular belt which transports the bottles along the length of the conveyor.

The modular belt is made from individual plastic modules that are connected to each other using rods. Thanks to its robust design it guarantees effective transport and easy cleaning.

These conveyors can include straight sections, sections with vertical elevations, etc., which are supported on legs that rest on the floor or braces that hang from the warehouse ceiling (when the warehouse structure allows it).

Upon request, the mass conveyor can be covered to keep external dust and other objects off the modular belt.

The conveyor is comprised of a stainless steel structure with legs that rest on the floor. The conveyor belt, which carries the bottles, rests on this structure.

The table top conveyor can include vacuum or not, depending on whether it will transport empty bottles or empty bottles inserted in pucks.

In particular, our table top conveyors with vacuum are especially designed for flat-base empty bottles. By adding vacuum, we ensure the necessary stability of the bottles on the conveyor. A flexible tube connects the vacuum nozzle to the fan inside the conveyor. The fan generates the necessary vacuum through the perforations and enables the bottles to stick to the belt.

There are different configurations available based on the type of bottle: X-BOX transfer, fixed guides on curves/transfers, double/roller lateral guides, and covered.

Guides can be adjusted quickly and simply without tools, unlike other conveyor systems.

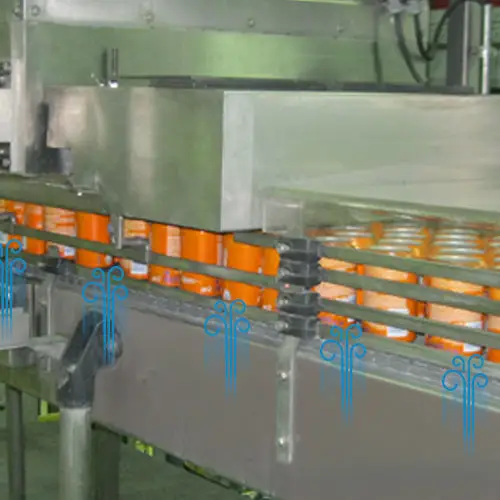

An air conveyor for various types of lightweight packaging from different industries. It can accumulate and smoothly transport at high speeds cans, aluminum trays, plastic or polystyrene trays, cartons, etc.

POSIJET CANS/POSIJET AIR CUSHION System: The transported product is propelled by a low-pressure air flow originating from the base of the conveyor, through a perforated plate.

It can feed products unloaded from pallets to the filler, in one or multiple rows. Optional detection of defective products (such as damaged cans, for example).

In an industrial environment where efficiency and precision are essential, conveyors play a crucial role. At POSIMAT, we design and manufacture transport systems tailored to our customers' specific needs, helping to maximize productivity, minimize operating costs, and ensure a continuous flow of containers and bottles.

Our conveyors not only facilitate the movement of products but also optimize key processes such as filling, labeling, or packaging. With decades of experience and a focus on innovation, we have developed unique solutions for a wide range of industries, from food and beverages to cosmetics and pharmaceuticals.

Choosing POSIMAT as your strategic partner means accessing solutions designed to maximize the efficiency of your production line. Our conveyors stand out not only for their efficiency and quality but also for the tangible benefits they offer to companies of any size and sector.

Every production line is unique, and at POSIMAT, we design personalized conveyors that integrate seamlessly into our customers' facilities.

Our systems are designed to optimize energy use, reduce maintenance, and minimize downtime.

Made from high-quality materials, our conveyors are designed to withstand the demands of the most challenging industrial environments.

We invest in technology and development to offer the most advanced solutions in the market.

At POSIMAT, we offer a wide range of industrial conveyors designed to meet the specific needs of each client. From systems for handling large volumes to specialized conveyors for delicate objects, our solutions guarantee efficiency, precision, and reliability in every production process.

Designed to transport unstable bottles at high speed, ensuring high line efficiency without stoppages and gentle handling of the bottles. Vertijet is the only air conveyor in the market capable of inclinations of up to 90º, optimizing plant space.

The POSIMAT mass conveyor is perfect for moving large quantities of products simultaneously. Thanks to its modular design, it easily adapts to different line configurations, improving productivity and reducing downtime.

This conveyor is ideal for production lines requiring robustness and continuity. With or without vacuum, chain conveyors ensure superior stability when transporting containers at high speed, guaranteeing high efficiency and the best handling of bottles, regardless of their size or shape.

Specifically designed for lightweight objects such as cardboard boxes, aluminum or steel cans, or plastic trays, our air conveyors provide safe and fast handling of objects. Their airflow technology ensures product integrity during high-speed processes.

At POSIMAT, we understand that every business has unique needs. That’s why our design and manufacturing process combines advanced technology, technical expertise, and a fully customized approach to ensure our industrial conveyors perfectly meet each client’s requirements.

We study production flows, product types, and specific working conditions to offer tailored solutions.

We manufacture in-house using durable materials and install conveyors directly on our clients’ production lines.

At POSIMAT, we work with leading companies from various industries looking to optimize their production lines with innovative and reliable solutions. Our experience enables us to adapt to the specific needs of each industry, ensuring efficiency, safety, and precision in all processes.

From high-speed lines in the food industry to delicate systems for pharmaceutical products, our industrial conveyors are designed to meet the most demanding challenges. Discover how our conveyors add value across different sectors: