It offers one of the highest performances in robotic unscrambling of bottles on the market, per single robot unit. Line bottle transition system using technology with optimal cost and maximum efficiency, based on technologies designed, manufactured and tested by POSIMAT during its long experience. The use of equipment manufactured by third parties (such as magnetic transport) is limited to guarantee the quality and speed of POSIMAT's usual technical service.

For filling lines with and without puck.

Simple to operate. Low maintenance.

No format changes.

It offers one of the highest performances in container unscrambling, reaching productions of up to 115 units/min with a single robot unit.

Transition system for bottles from the line using cost-effective technology and maximum efficiency, based on technologies designed, manufactured, and tested by POSIMAT during its extensive experience. The use of third-party manufactured equipment (such as magnetic transport) is limited to ensure POSIMAT's quality and quick technical service.

No mechanical parts to pre-position bottles that could damage them (such as brushes, vibrators, etc.). No format parts.

For filling lines with and without pucks.

Robotic unscramblers are automated devices designed to organize and orient containers, especially empty plastic bottles, in production lines. Their main function is to ensure that each container is correctly aligned before being filled or processed, optimizing efficiency and reducing errors in the production chain.

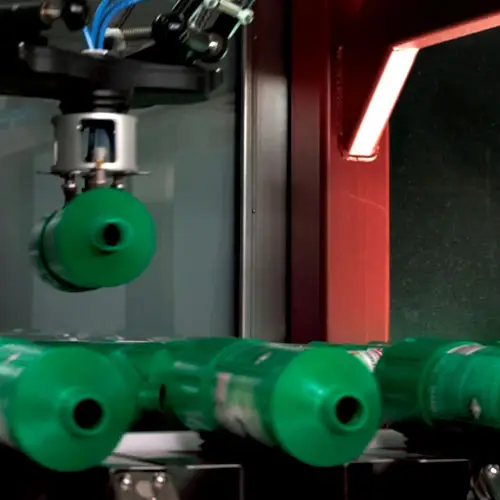

These systems use robotic arms equipped with suction cups, along with artificial vision systems, to identify the position and orientation of each container. Once detected, the robots pick up the containers and place them in the desired position on the production line. This process is highly flexible, allowing for the handling of a wide variety of container shapes and sizes without manual adjustments or the need for format parts.

Leading companies in the industry, such as POSIMAT, have developed advanced solutions in this field. For example, the POSIROBOT model offers one of the highest performances in container unscrambling, reaching production speeds of up to 115 units per minute with a single robotic unit. This system is characterized by its operational simplicity, the absence of mechanical parts that could damage containers, and the elimination of format changes, making it easy to use and maintain.

Another innovation is COMPACTBOT, recognized as the most compact robotic unscrambler on the market, ideal for production lines with limited space or those handling a wide variety of containers. This equipment allows for quick and simple automation of the filling line without the need for format parts, streamlining processes and reducing costs.

In the packaging sector, efficiency and precision are key to optimized production. POSIMAT's robotic unscramblers stand out for their innovation, operational simplicity, and ability to handle a wide variety of containers without manual adjustments.

Unlike other systems, POSIMAT's robotic unscramblers do not require format changes. This means they can handle different container shapes and sizes without costly and complex mechanical adjustments.

POSIMAT's exclusive design avoids the use of mechanical mechanisms that could damage containers. This is especially useful for lightweight or delicate materials, ensuring smooth and precise handling.

The POSIROBOT model by POSIMAT can unscramble up to 115 containers per minute with a single robotic unit, outperforming many traditional systems that require multiple robots to achieve the same capacity.

COMPACTBOT, the most compact robotic unscrambler on the market, is ideal for production lines with limited space. Its optimized design facilitates integration into both new and existing lines without major modifications.

Since POSIMAT's systems do not require format parts or mechanical adjustments, they reduce downtime and maintenance costs, ensuring a faster return on investment for manufacturers.

Choosing a robotic unscrambler for a production line is not only about evaluating technical performance, but also about trusting the manufacturer behind it. With over 40 years of industry leadership, POSIMAT combines innovation, quality, and unparalleled global service to offer the best unscrambling solutions.

POSIMAT designs its equipment with a focus on low maintenance and high durability, ensuring optimal performance with minimal operating costs. Their robust engineering and absence of format parts make robotic unscramblers a cost-effective long-term investment.

Since its founding, POSIMAT has revolutionized the container feeding and unscrambling market. With a presence in over 90 countries, its reputation is built on quality, innovation, and customer satisfaction.

POSIMAT not only manufactures cutting-edge equipment but also ensures top-tier after-sales service. With a worldwide technical assistance network, the company guarantees:

Behind every POSIMAT machine is a team of experts with decades of industry experience. From the design phase to implementation and maintenance, customers receive personalized guidance to ensure their investment is the best choice for their production needs.

By choosing a POSIMAT robotic unscrambler, companies not only acquire cutting-edge technology but also the peace of mind of working with a global leader in container feeding and unscrambling solutions. With a combination of efficiency, reliability, and worldwide service, POSIMAT is the smart choice for any industry seeking seamless automation.