POSIMAT designs feeders for all types of caps, applying its proven technology from over 40 years of experience in unscrambling plastic bottles. The unscrambler is based on gravity and air, without using noisy vibrating systems with difficult-to-carry-out format changes.

Our feeders receive caps in bulk, place them in the desired position, and supply them in a predetermined manner to the next machine using only format parts designed for this purpose.

POSIMAT offers a wide range of feeders to provide the best solution for each type of cap and production.

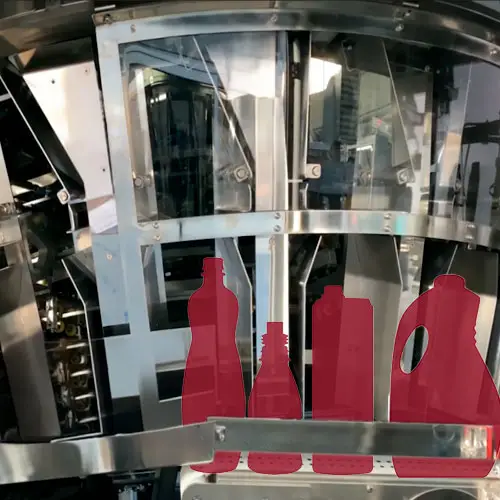

The N series Access bottle unscramblers for plastic bottles are known for their simplicity of operation, efficiency, and virtually maintenance-free design. Suitable for a wide variety of bottle shapes and sizes. Format change is simply done by plugging and unplugging selectors/funnels for the desired format, without the need for tools or adjustments. These format changes can be easily performed by a line operator in a short period of time.

Optionally, bottles can be transported by pucks.

It offers one of the highest performances in container unscrambling, reaching productions of up to 115 units/min with a single robot unit.

Transition system for bottles from the line using cost-effective technology and maximum efficiency, based on technologies designed, manufactured, and tested by POSIMAT during its extensive experience. The use of third-party manufactured equipment (such as magnetic transport) is limited to ensure POSIMAT's quality and quick technical service.

No mechanical parts to pre-position bottles that could damage them (such as brushes, vibrators, etc.). No format parts.

For filling lines with and without pucks.

It is the only fully adjustable automatic format change system on the market, activated by simply pressing a button. This system is available in the Access, Monochute, and Multichute series of unscramblers.

The advantages provided by the POSIFLEX system include quick format changes (instantaneous, in less than 1 minute) and the flexibility to add future formats by entering the parameters of the new bottle through the HMI.

Especially suitable for industries dealing with many formats, as it saves changeover time storage room for the change parts.

The POSIRINSER rinser cleans containers using air blowing (which can be ionized). It can be installed in monobloc with a POSIMAT unscrambler or installed as a standalone machine.

Containers are inverted and cleaned with several air nozzles, directed inside the container, in addition, vacuuming is applied to dispose of any loose particles.

There is also a version with water cleaning.

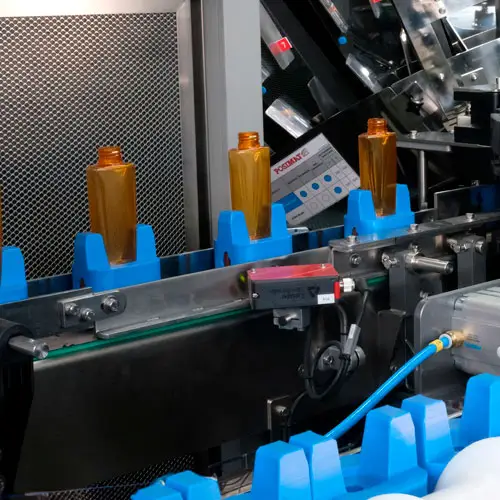

Whether it's because bottles are unstable or in other to optimize flexibility and speed in line format changes, some lines transport bottles inside pucks (also called godets).

The POSIPUCKS unscrabler perfectly inserts bottles into pucks and can also utilize any of POSIMAT's format change systems: manual or automatic.

The pucks enter empty from the end of the line and all of them exit the unscrambler with a bottle inside. No puck is sent to the filling line without a bottle.

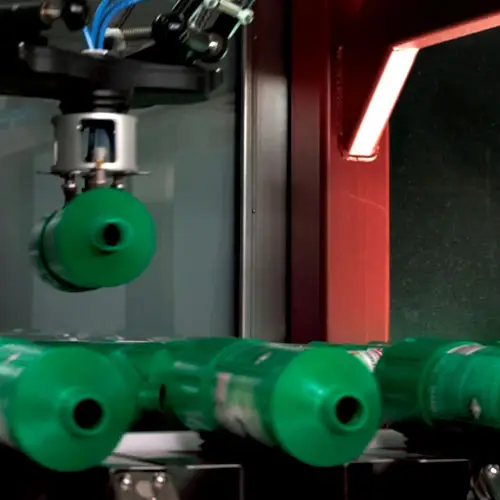

The POSIBOT is designed to work with all types of containers and other objects of different geometric shapes, especially those with very similar base and height size.

It features a system with suction cups that rotates the containers or objects to be unscrambled between 0º and 360º and gently places them on the output conveyor automatically, without pressure.

Format change is done by manually replacing the format parts without the need for adjustments or tools, in less than 5 minutes and without the involvement of qualified personnel.

This model is specially designed to operate fully automatically, without a dedicated operator.

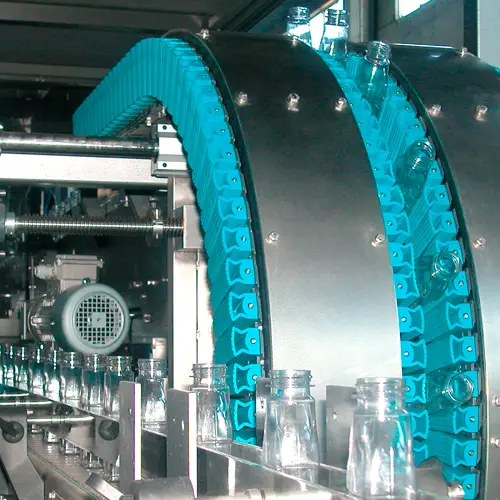

The POSIPHARMA bottle unscrambler is designed to unscramble wide-mouth bottles and large-diameter caps at productions of up to 300 bpm.

Its format change is done by manually changing format parts without the need for adjustments or tools, in less than 5 minutes and without the need for qualified personnel.

Specially designed model to operate fully automatically, without the need for dedicated operator supervision.

A small bottle unscrambler, typically for ophthalmic drops of 5ml and 10ml. Compact design capable of reaching productions of up to 120 units/minute.

It does not use compressed air.

Its design adapts to the GMP requirements of each client, making it ideal for automation solutions for the pharmaceutical industry.

Centrifugal bottle sorter, specially designed for the pharmaceutical sector for small-sized containers (typically ophthalmic drops or similar of 5ml and 10ml).

The machine is designed following GMP manufacturing guidelines, applicable in the pharmaceutical and cosmetic industries.

The tools and parts in contact with the bottles are easy to remove, handle, and sterilize in autoclaves.

Does not require compressed air for operation.