The MONOCHUTE and MULTICHUTE series are high-production models of bottle unscramblers suitable for all types of bottles and shapes, including bottles with flat or petaloid bases. They are the perfect ally to ensure high Overall Equipment Effectiveness (OEE) in any industry (soft drinks, water, dairy beverages, cosmetics, detergents, lubricants, etc.). Suitable for lines with or without pucks (also known as carriers).

The operating system is standard for all POSIMAT equipment, utilizing only gravity and air: no ramps, hooks, pulleys, or springs that may become misaligned.

Its ACCESS-type cabin allows for total control from the outside as well as access for inspection, cleaning, and lubrication (CIL).

A small bottle unscrambler, typically for ophthalmic drops of 5ml and 10ml. Compact design capable of reaching productions of up to 120 units/minute.

It does not use compressed air.

Its design adapts to the GMP requirements of each client, making it ideal for automation solutions for the pharmaceutical industry.

Centrifugal bottle sorter, specially designed for the pharmaceutical sector for small-sized containers (typically ophthalmic drops or similar of 5ml and 10ml).

The machine is designed following GMP manufacturing guidelines, applicable in the pharmaceutical and cosmetic industries.

The tools and parts in contact with the bottles are easy to remove, handle, and sterilize in autoclaves.

Does not require compressed air for operation.

Designed for unscrambling plastic tubes for any industry: cosmetics (mascara, dental hygiene, etc.), construction/DIY (silicone tubes), plastic cartridges of any type, etc.

POSIMAT tube unscramblers can deliver containers horizontally, side by side, presenting them transversely to the next machine: screen printing equipment, filler, etc.

Tube unscramblers can be manufactured in MASTER or ACCESS execution.

The combination of a bottle unscrambler with a Bottle Transfer Unit (BTU) allows for the safe transfer of unstable bottles to the filler. The BTU transfers the bottles into pucks (also known as godets).

Bottles can be transferred with or without prior orientation (depending on whether the bottle or puck is asymmetrical) to be inserted into the line's pucks.

The system is compatible with various types of pucks, including free-fall pucks, pucks with sides for labeling, asymmetrical pucks, etc.

The POSIPHARMA bottle unscrambler is designed to unscramble wide-mouth bottles and large-diameter caps at productions of up to 300 bpm.

Its format change is done by manually changing format parts without the need for adjustments or tools, in less than 5 minutes and without the need for qualified personnel.

Specially designed model to operate fully automatically, without the need for dedicated operator supervision.

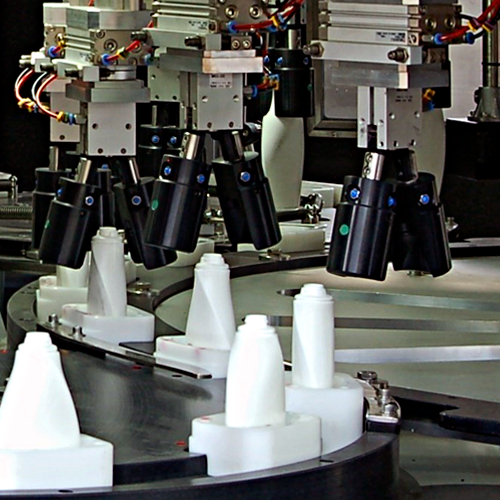

The POSIBOT is designed to work with all types of containers and other objects of different geometric shapes, especially those with very similar base and height size.

It features a system with suction cups that rotates the containers or objects to be unscrambled between 0º and 360º and gently places them on the output conveyor automatically, without pressure.

Format change is done by manually replacing the format parts without the need for adjustments or tools, in less than 5 minutes and without the involvement of qualified personnel.

This model is specially designed to operate fully automatically, without a dedicated operator.

It is the only fully adjustable automatic format change system on the market, activated by simply pressing a button. This system is available in the Access, Monochute, and Multichute series of unscramblers.

The advantages provided by the POSIFLEX system include quick format changes (instantaneous, in less than 1 minute) and the flexibility to add future formats by entering the parameters of the new bottle through the HMI.

Especially suitable for industries dealing with many formats, as it saves changeover time storage room for the change parts.

Whether it's because bottles are unstable or in other to optimize flexibility and speed in line format changes, some lines transport bottles inside pucks (also called godets).

The POSIPUCKS unscrabler perfectly inserts bottles into pucks and can also utilize any of POSIMAT's format change systems: manual or automatic.

The pucks enter empty from the end of the line and all of them exit the unscrambler with a bottle inside. No puck is sent to the filling line without a bottle.

The ACCESS BI-N bottle unscrambler has two bowls with a single bottle infeed and outfeed and it can reach high production speeds.

Integrating a bottle unscrambler between the blow molder and the filler provides a bottle buffer that absorbs the stops upstream and downstream of the line, increasing the total line efficiency (OEE) by more than 15%.

The N series Access bottle unscramblers for plastic bottles are known for their simplicity of operation, efficiency, and virtually maintenance-free design. Suitable for a wide variety of bottle shapes and sizes. Format change is simply done by plugging and unplugging selectors/funnels for the desired format, without the need for tools or adjustments. These format changes can be easily performed by a line operator in a short period of time.

Optionally, bottles can be transported by pucks.

Plastic bottle unscramblers, characterized by their simplicity of operation, efficiency, and virtually zero maintenance. Suitable for a wide variety of bottle shapes and sizes.

Format change simply by plugging and unplugging the new format selectors/funnels, without the need for tools or adjustments. These format changes can be easily performed by a line operator in a short amount of time.

It offers one of the highest performances in container unscrambling, reaching productions of up to 115 units/min with a single robot unit.

Transition system for bottles from the line using cost-effective technology and maximum efficiency, based on technologies designed, manufactured, and tested by POSIMAT during its extensive experience. The use of third-party manufactured equipment (such as magnetic transport) is limited to ensure POSIMAT's quality and quick technical service.

No mechanical parts to pre-position bottles that could damage them (such as brushes, vibrators, etc.). No format parts.

For filling lines with and without pucks.

POSIMAT designs feeders for all types of caps, applying its proven technology from over 40 years of experience in unscrambling plastic bottles. The unscrambler is based on gravity and air, without using noisy vibrating systems with difficult-to-carry-out format changes.

Our feeders receive caps in bulk, place them in the desired position, and supply them in a predetermined manner to the next machine using only format parts designed for this purpose.

POSIMAT offers a wide range of feeders to provide the best solution for each type of cap and production.

POSIJET, the only air conveyor with dual guidance. It efficiently handles bottles that other systems cannot transport.

A dual-guide profile encapsulates the bottle above and below the neck ring, avoiding leaving marks on the bottle neck and providing greater stability even at very high line speeds. Its unique bidirectional orifice model precisely directs the airflow around the neck ring and body of the bottle. This reduces pollution levels and jams, increases bottle speed, and keeps them upright at high speeds.

Effective with short-neck bottles. With Posijet, the airflow is precisely directed, able to concentrate on desired points of the bottle, even on short-neck bottles. Inclinations and declines of up to 90 degrees allow space savings in the production plant.

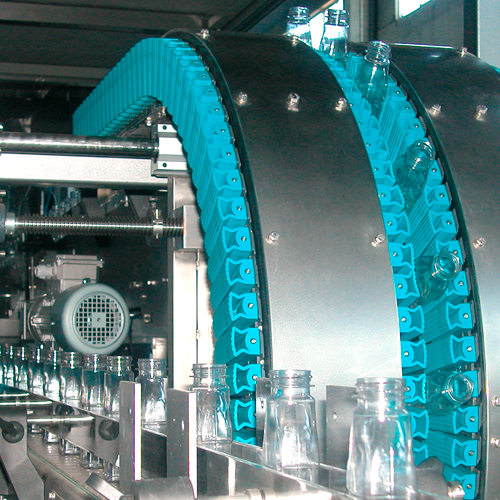

Mass conveyors have a stainless steel structure. Inside is the modular belt which transports the bottles along the length of the conveyor.

The modular belt is made from individual plastic modules that are connected to each other using rods. Thanks to its robust design it guarantees effective transport and easy cleaning.

These conveyors can include straight sections, sections with vertical elevations, etc., which are supported on legs that rest on the floor or braces that hang from the warehouse ceiling (when the warehouse structure allows it).

Upon request, the mass conveyor can be covered to keep external dust and other objects off the modular belt.

The conveyor is comprised of a stainless steel structure with legs that rest on the floor. The conveyor belt, which carries the bottles, rests on this structure.

The table top conveyor can include vacuum or not, depending on whether it will transport empty bottles or empty bottles inserted in pucks.

In particular, our table top conveyors with vacuum are especially designed for flat-base empty bottles. By adding vacuum, we ensure the necessary stability of the bottles on the conveyor. A flexible tube connects the vacuum nozzle to the fan inside the conveyor. The fan generates the necessary vacuum through the perforations and enables the bottles to stick to the belt.

There are different configurations available based on the type of bottle: X-BOX transfer, fixed guides on curves/transfers, double/roller lateral guides, and covered.

Guides can be adjusted quickly and simply without tools, unlike other conveyor systems.

An air conveyor for various types of lightweight packaging from different industries. It can accumulate and smoothly transport at high speeds cans, aluminum trays, plastic or polystyrene trays, cartons, etc.

POSIJET CANS/POSIJET AIR CUSHION System: The transported product is propelled by a low-pressure air flow originating from the base of the conveyor, through a perforated plate.

It can feed products unloaded from pallets to the filler, in one or multiple rows. Optional detection of defective products (such as damaged cans, for example).

The DEPEMAT empty bottle depalletizer is a fully automatic equipment specifically designed to efficiently and reliably depalletize plastic bottles from pallets for supply to the POSIMAT plastic bottle unscrambler.

POSIMAT also offers a new generation of robotic depalletizers, designed with a modular concept using a robotic arm. Each solution is tailored to the application to increase performance and efficiency through robotic automation.

Adaptable to all types of containers / bottles / jugs and pallet configurations.

The robotic system allows handling of all types of separator trays, flat and with edges folded up or down.

Semi-automatic machine for easily and reliably tipping boxes or gaylords, full of plastic bottles or other containers, into the unscrambler hopper, is a filling line.

It can tip cardboard or plastic boxes as well as octavins (octagonal boxes) on pallets.

The operator only needs to open the box and the inner plastic bag if there is one. Once the box is placed in the box tipper using a forklift or pallet jack, with the doors closed, the box is elevated and gradually tilted, safely tipping the contents into the hopper.

The belt orientor is designed to work with asymmetric bottles A detection system determines the position of the bottles, at the entrance of the machine; bottles are then turned to the desired position by two belts.

Once a bottle enters the orientor, a detection system recognizes its position and sends a signal to the turning unit.The turning unit activates two servomotors that rotate the bottle though a set of transmission belts, pulleys and orienting belts.

The detection unit is composed of a group of photo eyes or cameras which detect the differential feature of the bottle. After the automatic reading, the detection system sends a signal to the servomotors which activate the turning unit.

GIRAMAT is a machine designed to reorient bottles that have left an unscrambler, if they must be faced towards a particular direction.

There are several models available according to the speeds required, elements to be detected, and layout needs.

The differentiating feature might be an asymmetry, a handle, or simply the text or color, the threads on the bottle's neck, etc.

The POSIRINSER rinser cleans containers using air blowing (which can be ionized). It can be installed in monobloc with a POSIMAT unscrambler or installed as a standalone machine.

Containers are inverted and cleaned with several air nozzles, directed inside the container, in addition, vacuuming is applied to dispose of any loose particles.

There is also a version with water cleaning.

It is the only format change system in the market for a bottle unscrambler that is fully adjustable automatically and instantly.

Simply by pressing a button, the format change is completed in less than 1 minute.

This system is available on unscrambler in the Access, Monochute, and Multichute series.

It allows adding bottles in the future without the need for new parts, reducing wait time (manufacturing), avoiding economic investment, and solving the problem of storing format parts.

Especially suitable for industries that frequently change formats very frequently or have many different bottle designs.

The "N" manual format change is performed by manually removing the set of format parts and replacing them with those corresponding to the new bottle, without the need for tools or adjustments, in a short period of time.

The format set simply consists of selection boxes (pieces where the bottle goes into, from the loading disc, and is pre-positioned horizontally) and funnels (where the bottle descends and is positioned vertically).

All format parts are color-coded.

Due to its simplicity, it can be carried out by unskilled personnel.

The system allows adding bottles of different sizes, shapes, colors, and materials in the future.

POSIMAT’s Fixed In-built Silo is a compact, efficient storage solution designed to sit atop the access cabin of an ACCESS unscrambler, providing a direct and seamless feed for empty plastic bottles into the production line. Its design allows for reliable, steady bottle flow while saving floor space and minimizing manual intervention, making it ideal for facilities with limited space but high efficiency needs.

Sometime also known as “big bag”, POSIMAT's Tote System is a smart solution for handling empty plastic containers, offering a mobile, stackable storage solution designed to optimize logistics in filling lines. With totes, bottles are stored efficiently, reducing the need for excessive packaging materials and manual handling, while creating a safer, more organized workspace. These totes are easily transported by a forklift, minimizing labor costs and safety risks, making them ideal for manufacturers aiming to streamline their operations and improve sustainability.

Empty bottle silos can increase filling line efficiency by up to 15%. Allowing bottles to accumulate helps prevent line stoppages when any machine, whether upstream (bottle blow molder, depalletizer) or downstream (filler, labeler, case packer), stops.

The POSISILO empty bottle storage system consists of a patented system that revolutionizes the bottle outlet system, ensuring zero pressure. An extremely delicate system with bottles guarantees the best handling of containers to prevent damage or deformation.

The ramp opens and closes automatically according to the downstream line feeding needs.